Welcome to the official website of Shenzhen Dankai Technology Co., Ltd.!

Sitemap | contact us | Online message | CN

Telephone:

+8615158121839Hot key words:Polyperfluoroethylene propylene(FEP/F46) PTFE Teflon series PFA PVDF

News

Telephone:

+8615158121839Information details

PTFE tube weight calculation formula

- Categories:Industry news

- Author:PFA tube lady

- Origin:PFA tube lady

- Time of issue:2000-08-10 15:23

- Views:

PTFE tube weight calculation formula

- Categories:Industry news

- Author:PFA tube lady

- Origin:PFA tube lady

- Time of issue:2000-08-10 15:23

- Views:

1. Calculating formula for weight of PTFE tube

PTFE tube, scientific name polytetrafluoroethylene tube (F4 tube for short), PTFE tube is extruded with high-quality plunger, using special processing technology to make the steel tube and plastic tube tightly combined, can withstand positive pressure 1.6Mpa , Negative pressure: 77Kpa; it can be used normally within -60℃~+260℃, with reliable and excellent corrosion resistance. Transporting highly corrosive gases and liquids at high temperatures cannot be replaced by other pipelines.

PTFE tubes are widely used in the fields of machinery, chemical industry, aviation, electrical and electronics, defense industry, cutting-edge technology, medical and health, and electrical insulation.

Then, how do you calculate the weight of the PTFE tube?

Let me give you an example, the inner diameter is 4, the outer diameter is 6

Example: PTFE tube inner diameter 4 outer diameter 6

Weight per meter: (outer diameter + inner diameter) * (outer diameter-inner diameter) *1.74/1000

(6+4)*(6-4)*1.74/1000=0.0348kg

Weight per 100m: Weight per meter*100=Weight per meter

0.0348*100=3.48 (Tetrafluoro tube with an outer diameter of 6, an inner diameter of 4, the weight of a hundred meters is 3.48kg)

This is an algorithm when the inner and outer diameters are known. There are other algorithms, such as

Knowing the inner diameter 4 and the wall thickness 1. What is the outer diameter?

Inner diameter + wall thickness + wall thickness = outer diameter. 4+1+1=6, inner diameter 4, outer diameter 6

Knowing the outer diameter of 6, the wall thickness of 1, find the inner diameter?

Outer diameter 6-wall thickness 1-wall thickness 1=inner diameter, 6-1-1=4

The inner and outer diameter can be set according to the formula. Don't ask me the origin of the formula, it is too far away.

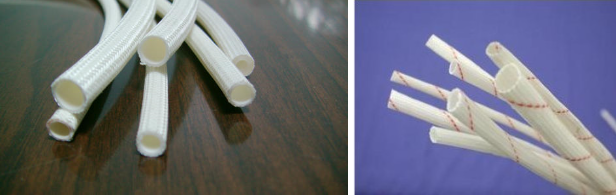

Picture 1: PTFE tube source: Shenzhen Dankai

PTFE tube features: PTFE tube has excellent chemical stability, can withstand all strong acids, strong alkalis, strong oxidants, and does not interact with various organic solvents. PTFE has a wide operating temperature range. It can be used for a long time at -180℃~250℃ under normal pressure. After 1000h of treatment at 250℃, its mechanical properties will change little. PTFE has a very low friction factor, is a good anti-friction, self-lubricating material, its static friction coefficient is less than the dynamic friction coefficient, so it has the advantages of low starting resistance and smooth running when used to make bearings. Because PTFE is non-polar, heat-resistant and does not absorb water, it is also an excellent electrical insulating material. It also has excellent aging resistance, non-stickiness and non-combustibility.

The manufactured bars, tubes, films, bearings, gaskets, valves and other special profiles and parts are widely used in machinery, chemical industry, aviation, electrical and electronics, defense industry, cutting-edge technology, medical and health, and electrical insulation.

2. Teflon tube for coffee machine

Shenzhen Dankai Technology Co., Ltd. specializes in R&D and sales of fluoroplastic materials. It has advanced equipment and a senior R&D team. It has cooperation with Huawei, Midea, ZTE, Intel, AirTAC, and Foxconn. The company’s main products are PTFE Ethylene pipes, polyperfluoroethylene propylene pipes, soluble polytetrafluoroethylene, polyvinylidene fluoride, and can process and produce various specifications of fluoroplastic products according to customer requirements.

The PTFE tube is extruded with high-quality plunger. It adopts a special processing technology to make the steel pipe and the plastic tube tightly combined. It can withstand a positive pressure of 1.6Mpa, a negative pressure: 77Kpa; it can be at -60℃~+260 Normal use within ℃, with reliable and excellent corrosion resistance. Transporting highly corrosive gases and liquids at high temperatures cannot be replaced by other pipelines.

PTFE tube performance: strong acid resistance: strong alkali chemical reagent high temperature self-lubricating

PTFE tube material: PTFE resin

PTFE tube operating temperature: -80~+260℃

Polytetrafluoroethylene (PTFE) has excellent chemical stability, can withstand all strong acids, strong alkalis, and strong oxidants, and does not interact with various organic solvents. PTFE has a wide operating temperature range. It can be used for a long time at -180℃~250℃ under normal pressure. After 1000h of treatment at 250℃, its mechanical properties will change little. PTFE has a very low friction factor, is a good anti-friction, self-lubricating material, its static friction coefficient is less than the dynamic friction coefficient, so it has the advantages of low starting resistance and smooth running when used to make bearings.

Picture 2: Special Teflon tube for coffee machine Source: Shenzhen Dankai

Because PTFE is non-polar, heat-resistant and does not absorb water, it is also an excellent electrical insulating material. It also has excellent aging resistance, non-stickiness and non-combustibility. Various profiles and parts made of PTFE, such as bars, tubes, films, bearings, gaskets, valves, etc., are widely used in machinery, chemical industry, aviation, electrical and electronics, defense industry, cutting-edge technology, medical and health, and electrical insulation And other fields.

3. Insulating sleeve is a kind of insulating material, which is a collective term.

Insulating materials are divided into single insulation and composite insulation. Insulating sleeve manufacturer

The single insulation is insulated with pure porcelain or resin, often made into wall bushings, used for voltage levels of 35 kV and below. The insulating part is tubular, and the middle part is clamped or glued with flanges for fixing on the perforated wall.

The flange is generally gray cast iron. When the working current is greater than 1500A, non-magnetic materials are commonly used to reduce heat generation. The insulation structure of a single insulation sleeve is divided into two types: air cavity and air cavity short circuit. The air cavity bushing is used for voltage levels of 10 kV and below. There is an air cavity between the conductor and the porcelain sleeve as auxiliary insulation, which can reduce the bushing capacitance and increase the corona voltage and sliding voltage of the bushing. When the voltage level is higher (20-30 kV), corona will occur inside the air cavity and the above effects will be invalid. At this time, the air cavity short-circuit structure is adopted.

The inner wall of the porcelain sleeve of the porcelain sleeve is coated with semiconductor glaze, and the spring sheet is connected with the conductor to make the air cavity short-circuit, so as to eliminate the internal corona. However, corona and slip flash may still occur near the flange. Usually a large umbrella skirt is set on the surface of the porcelain sleeve on both sides near the flange, and a semi-conductive layer is coated near the flange to evenly distribute the electric field and improve the discharge characteristics of the sleeve.

Figure 3: Insulating sleeve source: Shenzhen Dankai

Composite insulation uses oil or gas as the insulating medium, generally made into transformer bushings or circuit breaker bushings, and is often used for voltage levels below 35 kV. The inner cavity between the conductor of the composite insulating sleeve and the porcelain sleeve is filled with transformer oil, which acts as a radial insulation.

When the voltage exceeds 35 kV, the conductor is covered with an insulating tube or cable to strengthen the insulation. The conductor structure of the composite insulating sleeve has two types: cable type and guide rod type. The cable-through type uses the lead-out cable of the transformer to directly pass through the bushing, which is convenient for installation. When the working current is greater than 600A, the installation of the cable-through structure is difficult, and the guide-rod structure is generally adopted.

Shenzhen DanKai Technology Co., Ltd. (ShenZhen DanKai Technology Co.,ltd.), whose predecessor is Dongguan Dandi Insulation Material Co., Ltd. Fluoroplastic Material Factory, established in 1998, specializes in FEP, PFA, PTFE and other fluoroplastic pipes R&D, production and sales of rod, sheet and film products and other insulating materials. The company has a senior R&D team with international standards and a production line of fluorine plastic products imported from abroad. Some fluoroplastic products have passed ISO9001, SGS, FDA certification, and have been fully affirmed by domestic and foreign cooperative customers such as Huawei, Foxconn, Midea, ZTE, Intel, and AirTAC. The main products of the company are: ①Tubes: Ptfe tube, Fep tube, Pfa tube, Pvdf tube; ②Heat shrinkable tube: Ptfe heat shrinkable tube, Fep heat shrinkable tube, Pfa heat shrinkable tube, Pvdf heat shrinkable tube; ③Plate rod Membrane: Ptfe board and rod film, Fep board and rod film, Pfa board and rod film, Pvdf board and rod film; ④Insulation materials: silica gel, PE, PVC, UPE, etc.; ⑤Special category: PFA imported connector, spiral tube, spring tube , Rotary cut tube, welding rod, tee, straight-through, gasket, joint, taper rod, flared tube, sealing tube, braided tube, bellows, etc. At the same time, fluorine plastic products of various specifications can be customized and processed according to customer requirements.

More news

Landline: 0755-29979617

Cell phone: 15818669373

Add WeChat, free sample

Follow the corporate public account

Shenzhen Dankai Technology Co., Ltd.

Address: Area B, 4th Floor, Building 1, North Yongfa Science and Technology Park, Yanchuan North, Chaoyang Road, Songgang Town, Bao'an District, Shenzhen

Tel: 0755-29979617 23127719 23127819

Fax: 86-0755-29979492

Follow us

Page copyright©1998-2024 Shenzhen Dan Kai Technology Co., Ltd. Guangdong 粤ICP备12071381号