Welcome to the official website of Shenzhen Dankai Technology Co., Ltd.!

Sitemap | contact us | Online message | CN

Telephone:

+8615158121839Hot key words:Polyperfluoroethylene propylene(FEP/F46) PTFE Teflon series PFA PVDF

News

Telephone:

+8615158121839Information details

What are the main differences between PFA tube and PTFE tube

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2004-08-29 10:03

- Views:

What are the main differences between PFA tube and PTFE tube

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2004-08-29 10:03

- Views:

1. There is no obvious difference between PFA (tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer) tube and PTFE (polytetrafluoroethylene) tube from the outside, the main difference may be reflected in the performance, Therefore, the actual uses of PFA tube and PTFE tube are also different. But what exactly it is has to be further analyzed.

Let's first look at the characteristics of PTFE pipe. It is a white opaque pipe with many forms, including conduits, hoses, pipe lining pipes, braided reinforced pipes and so on. After testing, PTFE tube has excellent high and low temperature resistance and chemical resistance, and can transport liquid or gas at a temperature of up to 260°C.

The PFA tube is made of melt-processable thermoplastic. Although it also has excellent stress crack resistance and bending life, it is obviously inferior to PTFE tube in terms of permeability. Because the content of metal ions in the PFA tube is very low, it can also maintain strong strength and burst pressure at higher temperatures.

It is precisely because of the excellent electrical properties of PTFE tube that it has become a suitable material in the electronics and electrical fields, mainly used for electrical insulation jackets, chemical transportation, heat exchangers, and chemical heavy anti-corrosion. The PFA tube can be used to make a variety of digestion tubes.

The appearance of the PFA digestion tube is translucent, and it also has many excellent properties, such as high and low temperature resistance, corrosion resistance, insulation resistance, pollution prevention and so on. The appearance is translucent. Because PFA material has very low dissolution and precipitation, it can be an ideal choice for storing standard materials and highly corrosive substances;

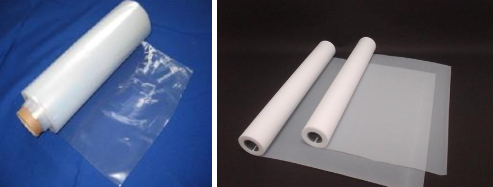

Figure 1: Source of PFA tube: Shenzhen Dankai

It seems that whether it is PFA tube or PTFE tube, they have their own unique properties, prompting them to play a role in various fields. There is no conflict between the applications of the two, and they can even make up for each other.

2. PFA film is extruded and blow molded from polyperfluoroethylene propylene resin, which has excellent resistance to high and low temperature, chemical corrosion resistance, high insulation, non-stickiness and light transmission. It can be used for a long time in the range of -80~200℃. It is resistant to high and low temperatures, and the high temperature is twice that of F4. It is non-sticky and highly insulating, and can be exposed to ozone and sunlight for a long time.

use:

Mainly used for the insulation of electrical components and wires at various frequencies.

It is suitable for use in various places with harsh working conditions. Such as: anti-corrosion, anti-sticking, explosion-proof, sight glass, and can also be used for high temperature bonding of specific materials.

The copolymer of tetrafluoroethylene and perfluoropropyl vinyl ether (PFA), also known as soluble polytetrafluoroethylene, completely maintains the excellent performance of polytetrafluoroethylene. The use temperature is -180∽260℃, and it has good mechanical and electrical properties. Insulation performance, outstanding heat resistance and low friction coefficient, flame retardant, low smoke, weather resistance, and good thermoplasticity.

Overview:

Soluble polytetrafluoroethylene sheet and film (PFA film) are made of tetrafluoroethylene and perfluoropropyl vinyl ether copolymer resin by extrusion or blow molding. They are mainly used for various anti-corrosion, sealing and insulation , Anti-sticking, high temperature resistance, oil resistance, non-combustibility and other spare parts; at the same time, it is also used as the insulation layer of electrical and electronic industries, high frequency and ultra high frequency insulators, and electrical insulation parts.

feature:

1. Appearance: smooth, transparent and flat surface

2. Physical and mechanical properties

Figure 2: Film (PFA film) Source: Shenzhen Dankai

FEP has a crystal melting point of 580F and a density of 2.15g/CC (grams per cubic centimeter). It is a soft plastic with lower tensile strength, wear resistance and creep resistance than many engineering plastics. It is chemically inert and has a low dielectric constant (2.1) in a wide temperature and frequency range. The material does not ignite and can prevent the spread of flames. It has excellent weather resistance, low friction coefficient, and can be used from low temperature to 392F. The material can be made into granular products for extrusion and molding, used as powder for fluidized bed and electrostatic coating, and can also be made into water dispersion. Semi-finished products include film, board, rod and single fiber. Its main purpose is to make linings for pipes and chemical equipment, surface layers of drums, and various wires and cables, such as aircraft hook wires, booster cables, alarm cables, flat cables and oil well logging cables. FEP film has been used as a thin coating for solar collectors. Polyperfluoroethylene propylene FEP or F46 is a copolymer of tetrafluoroethylene and hexafluoropropylene. The content of hexafluoropropylene is about 15%. It is a modified material of polytetrafluoroethylene. F-46 resin not only has similar characteristics to PTFE, but also has good processing properties of thermoplastics. Therefore, it makes up for the deficiencies of the difficult processing of PTFE, making it a material to replace PTFE, and is widely used in the production of wires and cables for electronic equipment transmission wires used under high temperature and high frequency, and internal connections in electronic computers. Insulation layer of wires, aerospace wires and special purpose installation wires, oil pump cables and winding wires of submersible motors. According to processing needs, F-46 can be divided into three types: pellets, dispersions and paints. Among them, the pellets can be used for molding, extrusion and injection molding according to their melt index; the dispersion is used for dipping and sintering; the paint is used for spraying.

More news

Landline: 0755-29979617

Cell phone: 15818669373

Add WeChat, free sample

Follow the corporate public account

Shenzhen Dankai Technology Co., Ltd.

Address: Area B, 4th Floor, Building 1, North Yongfa Science and Technology Park, Yanchuan North, Chaoyang Road, Songgang Town, Bao'an District, Shenzhen

Tel: 0755-29979617 23127719 23127819

Fax: 86-0755-29979492

Follow us

Page copyright©1998-2024 Shenzhen Dan Kai Technology Co., Ltd. Guangdong 粤ICP备12071381号