Welcome to the official website of Shenzhen Dankai Technology Co., Ltd.!

Sitemap | contact us | Online message | CN

Telephone:

+8615158121839Hot key words:Polyperfluoroethylene propylene(FEP/F46) PTFE Teflon series PFA PVDF

News

Telephone:

+8615158121839Information details

What is the difference between PFA and PTFE

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2004-08-29 10:03

- Views:

What is the difference between PFA and PTFE

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2004-08-29 10:03

- Views:

Polytetrafluoroethylene (PTFE) and perfluoroalkoxy resin (PFA) are two fluoroplastics that are widely used worldwide. Their properties are very similar. PFA may even be called "meltable polytetrafluoroethylene". ". So, what is the difference between them?

Molecular structure comparison

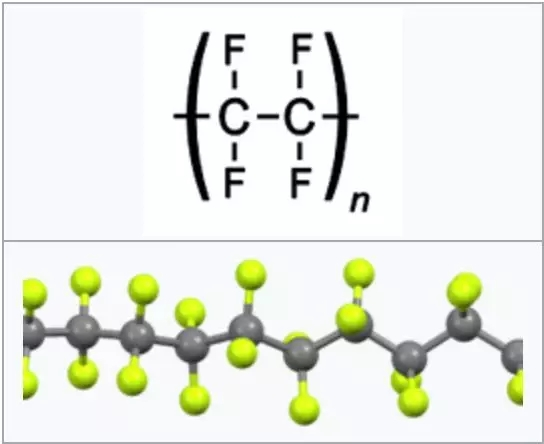

PTFE is polymerized by the monomer tetrafluoroethylene. DuPont discovered it for the first time in 1938. The most well-known PTFE brand is Teflon®. The figure below shows the structural formula of PTFE. The yellow balls represent fluorine atoms.

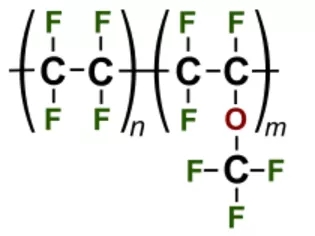

PFA has added perfluoroalkoxy, which is equivalent to replacing one fluorine atom in PTFE with perfluoroalkoxy. Like PTFE, the formulation of PFA was first invented by DuPont, and the most famous PFA formulation is Teflon PFA. In terms of molecular structure, the carbon chain of PFA is relatively short, and the degree of chain entanglement is higher. The figure below shows the structural formula of PFA.

Performance comparison

On the whole, the properties of PFA are very similar to PTFE. The biggest difference is that PFA can be melt processed, while PTFE cannot. This means that PFA can be processed using traditional injection molding and screw extrusion techniques.

PTFE solid is hydrophobic, so it is not easily affected by moisture and has a very low coefficient of friction; PFA is more susceptible to the effects of alternating wet and dry environments, but in terms of salt spray corrosion resistance, PFA has better performance than PTFE.

PFA has better elasticity than PTFE, especially in the use of pipes, but its resistance to repeated folding is slightly inferior to PTFE.

The dielectric constant of PFA is the same as PTFE, and the dissipation factor is very similar. However, the dielectric strength of PFA is three to four times that of PTFE.

Application field comparison

According to statistics, more than half of PTFE worldwide is used to make cables: including connecting wires, coaxial cables, etc. This is because PTFE has excellent dielectric properties, especially in the field of high-frequency radio. Combined with its high melting point, PTFE has become a high-performance alternative to polyethylene.

Due to its extremely low coefficient of friction, it is also used to make sliding bearings, gears, sliding plates, seals, gaskets, bushings, and even lubricants to reduce mechanical friction and improve energy utilization.

Due to its excellent chemical stability, PTFE is also used to make containers and pipes for storage and transportation of active or corrosive chemicals. Of course, the most daily application of PTFE is the non-stick coating of non-stick pans and kitchenware models. PTFE is also shown as a non-stick pan coated with PTFE in the following figure:

PFA is usually used in laboratory equipment, especially as a pipeline for important reactions or highly corrosive chemical reactions. Because PFA has strong chemical resistance, optical transparency and good flexibility, it can be very good. To avoid chemical pollution caused by metal ions, it has important applications in the field of analytical chemistry.

In thermal power plants, PFA is used as the lining of heat exchangers. Because the high-temperature gas is passed through the PFA-lined device, the temperature of the gas can be cooled without damaging the heat exchanger, thereby improving the energy efficiency of the entire plant.

In addition, the use of PFA as the sheet lining of chemical instruments has guaranteed corrosion resistance, and expensive alloys and metals can be replaced by carbon steel fiber reinforced plastics (FRPs). The picture below shows the PFA tube:

For a long time in the past, PTFE has been sought after by the industry because of its superior physical and chemical properties. However, the limitations of its processing methods also limit its application. PFA is actually an improved version of PTFE. Its performance is similar to that of PTFE material, but it has very good processing properties, allowing engineers to solve their problems.

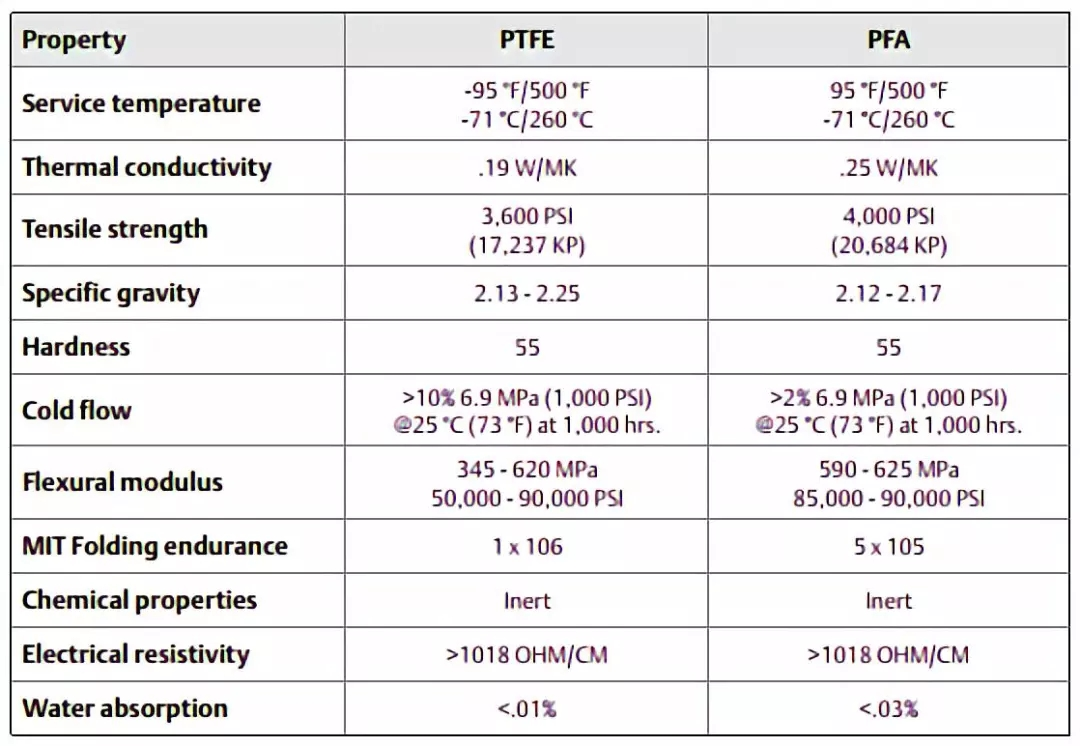

Finally, draw an important point for students who don’t like to read text. The performance comparison between PTFE and PFA is shown in the following table:

Shenzhen DanKai Technology Co., Ltd. (ShenZhen DanKai Technology Co.,ltd.), whose predecessor is Dongguan Dandi Insulation Material Co., Ltd. Fluoroplastic Material Factory, established in 1998, specializes in FEP, PFA, PTFE and other fluoroplastic pipes R&D, production and sales of rod, sheet and film products and other insulating materials. The company has a senior R&D team with international standards and a production line of fluorine plastic products imported from abroad. Some fluoroplastic products have passed ISO9001, SGS, FDA certification, and have been fully affirmed by domestic and foreign cooperative customers such as Huawei, Foxconn, Midea, ZTE, Intel, and AirTAC. The main products of the company are: ①Tubes: Ptfe tube, Fep tube, Pfa tube, Pvdf tube; ②Heat shrinkable tube: Ptfe heat shrinkable tube, Fep heat shrinkable tube, Pfa heat shrinkable tube, Pvdf heat shrinkable tube; ③Plate rod Membrane: Ptfe board and rod film, Fep board and rod film, Pfa board and rod film, Pvdf board and rod film; ④Insulation materials: silica gel, PE, PVC, UPE, etc.; ⑤Special category: PFA imported connector, spiral tube, spring tube , Rotary cut tube, welding rod, tee, straight-through, gasket, joint, taper rod, flared tube, sealing tube, braided tube, bellows, etc. At the same time, fluorine plastic products of various specifications can be customized and processed according to customer requirements.

More news

Landline: 0755-29979617

Cell phone: 15818669373

Add WeChat, free sample

Follow the corporate public account

Shenzhen Dankai Technology Co., Ltd.

Address: Area B, 4th Floor, Building 1, North Yongfa Science and Technology Park, Yanchuan North, Chaoyang Road, Songgang Town, Bao'an District, Shenzhen

Tel: 0755-29979617 23127719 23127819

Fax: 86-0755-29979492

Follow us

Page copyright©1998-2024 Shenzhen Dan Kai Technology Co., Ltd. Guangdong 粤ICP备12071381号