Welcome to the official website of Shenzhen Dankai Technology Co., Ltd.!

Sitemap | contact us | Online message | CN

Telephone:

+8615158121839Hot key words:Polyperfluoroethylene propylene(FEP/F46) PTFE Teflon series PFA PVDF

News

Telephone:

+8615158121839Information details

What are the performance of ptfe Teflon spring tube

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2005-08-13 10:03

- Views:

What are the performance of ptfe Teflon spring tube

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2005-08-13 10:03

- Views:

1. What material is Teflon? When we studied chemistry, we all learned polytetrafluoroethylene, molecular formula: C2F4, tetrafluoroethylene is mainly made from chloroform, and it can also be made from tetrafluorodichloroethane in the presence of chlorine trifluoride It is prepared by catalytic dechlorination. It is a colorless and odorless gas at room temperature, with a boiling point of -76.3°C, which can be liquefied under pressure, with a critical temperature of 33.3°C and a critical pressure of 3.92MPa. Unlike many other fluorohydrocarbons, tetrachloroethylene is toxic and is mainly used to produce polytetrafluoroethylene with a wide temperature range and high chemical stability; it can also be copolymerized with ethylene or hexafluoropropylene to prepare fluorine-containing insulating materials, or with Vinylidene fluoride copolymerization produces fluorine-containing fibers.

Teflon is the common name of Teflon, so Teflon is processed from Teflon and other materials.

Teflon is commonly known as "Plastic King", and is also known as "Teflon", "Teflon", "Teflon", "Teflon" and so on.

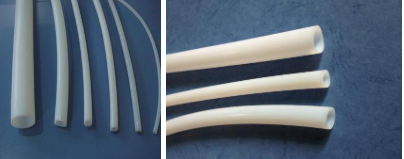

Picture 1: Teflon tube source: Shenzhen Dankai

Teflon tube product features

1. High chemical stability: can withstand all strong acids, including aqua regia, hydrofluoric acid, concentrated hydrochloric acid, nitric acid, fuming sulfuric acid, organic acids, etc., strong alkalis, strong oxidants, reducing agents and various organic solvents . It is very suitable for feeding high-purity chemicals.

2. Low coefficient of friction: The coefficient of friction is generally only 0.04, which is a very excellent self-lubricating material, and the coefficient of friction does not change with changes in temperature.

3. Excellent anti-sticking property, and the inner wall of the tube is not easy to adhere to colloids and chemicals.

4. Excellent aging resistance, can be used outdoors for a long time.

5. Excellent electrical insulation performance: PTFE is a highly non-polar material with good dielectric properties, great resistance, and a dielectric constant of about 2.0, which is the smallest among all electrical insulation materials.

6. Part of the tube has high transparency, and the internal fluid condition can be easily observed.

Teflon tube performance parameters

1. Withstand voltage: 150V-600V

2. Working temperature: -80℃~260℃

3. Melting point: 327℃

4. Flame retardancy: VW-1

5. Breakdown strength: 26KV/mm

6. Color: transparent, translucent, milky white.

2. Teflon spring tube

I believe everyone is familiar with springs. The spring tube is shaped like a spring. The difference is that the spring tube is generally made of transparent material. There are several important data for ordering a spring tube, the inner and outer diameter of the tube, the inner and outer diameter of the spring, and the length of the spring. To determine these five data, you can contact me.

The spring tube is made of soluble polytetrafluoroethylene PFA and polyperfluoroethylene propylene FEP in a spiral and spiral direction. It is characterized by greater flexibility and bendability. The minimum bending radius increases with the increase of the pipe diameter.

The spring tube has the characteristics of excellent high temperature resistance, corrosion resistance, and long service life. It is widely used in pesticide filling machines, sulfuric acid filling machines, food filling machines, various oil filling machines, medical instruments, instruments, and automobiles. Oil pipeline and other industries.

A special shaped tube with a closed end of the spring tube will deform within its elastic limit when the inside and outside of the tube are subjected to different pressures. The spring tube is a kind of pressure detecting element in the pressure measuring instrument.

The spring tube is a hollow tube that is made of elastic materials and bent into C-shaped, spiral, and coil-shaped shapes. The earliest spring tube was bent into a C shape, because it was invented by the Frenchman E. Bourdon, so it is also called Bourdon tube, and it is still widely used in modern times. Its free end is movable and its open end is fixed. Fluid is introduced into the tube, and under the action of fluid pressure, the spring tube deforms, and the free end produces linear displacement or angular displacement. The measurement range of the spring tube can be from tens of kilopascals to more than one gigapa. Common cross-sectional shapes are oval, flat, and round. Among them, the flat tube is suitable for low pressure, the round tube is suitable for high pressure, and the coiled coil spring tube can be used in instruments that require a large displacement of the spring tube.

Picture 2: Teflon spring tube source: Shenzhen Dankai

C-shaped tube: like "C" shape, applicable pressure range ≤10MPa, the standard angle of C-shaped tube is 270°.

1. Appearance: 1. The inner and outer surfaces of the pipe are smooth and flat, the cuts are neat, and the section is flat, without obvious cracks and potholes.

2. The size and range meet the requirements.

3. The bending angle of the spring tube is 270°, and there is no obvious inward contraction or outward expansion.

2. Material: Judge the material from the color.

3. The darker the color, the more timely.

4. For spiral tubes: the number of spiral turns meets the requirements.

Shenzhen DanKai Technology Co., Ltd. (ShenZhen DanKai Technology Co.,ltd.), whose predecessor is Dongguan Dandi Insulation Material Co., Ltd. Fluoroplastic Material Factory, established in 1998, specializes in FEP, PFA, PTFE and other fluoroplastic pipes R&D, production and sales of rod, sheet and film products and other insulating materials. The company has a senior R&D team with international standards and a production line of fluorine plastic products imported from abroad. Some fluoroplastic products have passed ISO9001, SGS, FDA certification, and have been fully affirmed by domestic and foreign cooperative customers such as Huawei, Foxconn, Midea, ZTE, Intel, and AirTAC. The main products of the company are: ①Tubes: Ptfe tube, Fep tube, Pfa tube, Pvdf tube; ②Heat shrinkable tube: Ptfe heat shrinkable tube, Fep heat shrinkable tube, Pfa heat shrinkable tube, Pvdf heat shrinkable tube; ③Plate rod Membrane: Ptfe board and rod film, Fep board and rod film, Pfa board and rod film, Pvdf board and rod film; ④Insulation materials: silica gel, PE, PVC, UPE, etc.; ⑤Special category: PFA imported connector, spiral tube, spring tube , Rotary cut tube, welding rod, tee, straight-through, gasket, joint, taper rod, flared tube, sealing tube, braided tube, bellows, etc. At the same time, fluorine plastic products of various specifications can be customized and processed according to customer requirements.

More news

Landline: 0755-29979617

Cell phone: 15818669373

Add WeChat, free sample

Follow the corporate public account

Shenzhen Dankai Technology Co., Ltd.

Address: Area B, 4th Floor, Building 1, North Yongfa Science and Technology Park, Yanchuan North, Chaoyang Road, Songgang Town, Bao'an District, Shenzhen

Tel: 0755-29979617 23127719 23127819

Fax: 86-0755-29979492

Follow us

Page copyright©1998-2024 Shenzhen Dan Kai Technology Co., Ltd. Guangdong 粤ICP备12071381号