Welcome to the official website of Shenzhen Dankai Technology Co., Ltd.!

Sitemap | contact us | Online message | CN

Telephone:

+8615158121839Hot key words:Polyperfluoroethylene propylene(FEP/F46) PTFE Teflon series PFA PVDF

News

Telephone:

+8615158121839Information details

What are the characteristics of polytetrafluoroethylene (PTFE)

- Categories:Industry news

- Author:Miss Teflon tube

- Origin:Miss Teflon tube

- Time of issue:2006-10-21 10:03

- Views:

What are the characteristics of polytetrafluoroethylene (PTFE)

- Categories:Industry news

- Author:Miss Teflon tube

- Origin:Miss Teflon tube

- Time of issue:2006-10-21 10:03

- Views:

1. Polytetrafluoroethylene, English name: Polytetrafluoroethylene, referred to as FTFE or F4.

Polytetrafluoroethylene is a polymer of tetrafluoroethylene. Polytetrafluoroethylene (Teflon or PTFE), commonly known as "Plastic King", was invented in 1938.

The F atom in the PTFE molecule covers the CC bond, and the CF bond has a high bond energy and is particularly stable. It is not corroded by any chemicals except for alkali metals and fluorine.

The F atom in the PTFE molecule is symmetrical, and the two elements in CF are covalently combined. There are no free electrons in the molecule, and the whole molecule is neutral. Make PTFE have excellent dielectric properties. Because there is an inert fluorine-containing shell outside the PTFE molecule, it has outstanding non-stick performance and low friction coefficient.

PTFE has outstanding excellent comprehensive properties, high temperature resistance, corrosion resistance, non-stick, self-lubricating, excellent dielectric properties, and a very low coefficient of friction. By adding any filler that can withstand the sintering temperature of PTFE, its mechanical properties can be greatly improved. At the same time, other excellent properties of PTFE are maintained. Filled varieties include glass fiber, metal, metal oxide, graphite, molybdenum disulfide, carbon fiber, polyimide, EKONOL... etc. The wear resistance and limit PV value can be increased by 1000 times.

PTFE has excellent chemical stability, corrosion resistance, airtightness, high lubrication and non-stick properties, electrical insulation and good aging resistance. It can work for a long time at a temperature of +250°C to -180°C. Except for molten sodium and liquid fluorine, it can withstand all other chemicals, and it will not change when boiled in aqua regia.

PTFE engineering plastics can be made into PTFE tubes, rods, belts, plates, films, etc. Generally used in corrosion-resistant pipelines, containers, pumps, valves, radar, high-frequency communication equipment, and radio equipment with high performance requirements. The dispersion can be used as the insulating dipping solution for various materials and the anticorrosive coating on the surface of metal, glass, and ceramics. Various PTFE rings, PTFE gaskets, PTFE packings, etc. are widely used for sealing various anticorrosive pipeline flanges. In addition, it can also be used for spinning, polytetrafluoroethylene fiber-fluorine fiber (foreign trade name is Teflon).

Polytetrafluoroethylene resin is mostly powder or dispersion. Polytetrafluoroethylene powder resin is white, odorless, tasteless and non-toxic powder. When processed into products, it becomes a transparent or opaque white material, wax-like, non-hydrophilic, smooth and non-sticky, and looks like polyethylene. Its density is as high as 2.14g/m3, which is the heaviest kind of plastic. According to the preparation method, there are three main types of polytetrafluoroethylene: suspension resin, dispersion resin and concentrated dispersion. my country's suspension resin accounted for 66.81%, and dispersion resin accounted for 31.19%.

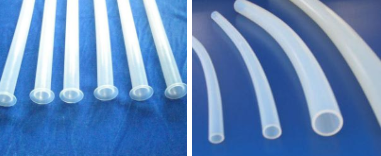

Picture 1: PTFE tube source: Shenzhen Dankai

Second, the application of suspension PTFE

Suspension method PTFE is mainly used to manufacture sealing rings, gaskets, etc. used in the machinery industry, as well as pumps, valves, pipe fittings and equipment linings used in chemical equipment, as well as electrical insulating parts and films. Suspension method PTFE is generally divided into the following three categories:

1. Micro powder:

The average diameter of the particles is 20~35μm, which can be used for compression molding.

2. Pelletizing material:

It has good powder flowability and large apparent density. Coarse particles (about 300μm in diameter) are used for automatic compression molding, hydroforming, and can also be used for general compression molding.

3. Pre-sintered material:

It can be processed into thinner and thinner products by the plunger method. Such as rods with a diameter of 5-50mm, pipes with a wall thickness of 3-25mm, etc.

Application of dispersion method PTFE

The dispersion method PTFE is mainly used to manufacture corrosion-resistant, high-temperature-resistant, high-dielectric wire and cable. In the chemical industry, it is mainly used to manufacture threaded sealing raw material tape, pipeline lining, etc.

4. High compression ratio powder:

Extrusion molding under the condition of compression ratio greater than 2500:1, suitable for processing into thin-walled thin tubes and wire insulation sheaths with a diameter of less than 2mm and a wall thickness of 0.2-0.5mm.

5. Medium compression ratio powder:

Extrusion under the condition of a compression ratio greater than 400:1, suitable for processing into medium-sized thin-walled tubes with a diameter of 2-15mm and a wall thickness of 0.5mm or more.

6. Low compression ratio powder:

Extrusion under the condition of compression ratio less than 300:1, suitable for processing into thicker pipes and thick rods with a diameter of 5mm or more.

Application of concentrated polytetrafluoroethylene dispersion

PTFE concentrated dispersion is mainly used as anti-stick coating in food, textile, printing and dyeing, papermaking and other industries, as well as impregnating glass cloth, asbestos, etc. In addition, it can also be used for glass fiber and porous materials.

Shenzhen DanKai Technology Co., Ltd. (ShenZhen DanKai Technology Co.,ltd.), whose predecessor is Dongguan Dandi Insulation Material Co., Ltd. Fluoroplastic Material Factory, established in 1998, specializes in FEP, PFA, PTFE and other fluoroplastic pipes R&D, production and sales of rod, sheet and film products and other insulating materials. The company has a senior R&D team with international standards and a production line of fluorine plastic products imported from abroad. Some fluoroplastic products have passed ISO9001, SGS, FDA certification, and have been fully affirmed by domestic and foreign cooperative customers such as Huawei, Foxconn, Midea, ZTE, Intel, and AirTAC. The main products of the company are: ①Tubes: Ptfe tube, Fep tube, Pfa tube, Pvdf tube; ②Heat shrinkable tube: Ptfe heat shrinkable tube, Fep heat shrinkable tube, Pfa heat shrinkable tube, Pvdf heat shrinkable tube; ③Plate rod Membrane: Ptfe board and rod film, Fep board and rod film, Pfa board and rod film, Pvdf board and rod film; ④Insulation materials: silica gel, PE, PVC, UPE, etc.; ⑤Special category: PFA imported connector, spiral tube, spring tube , Rotary cut tube, welding rod, tee, straight-through, gasket, joint, taper rod, flared tube, sealing tube, braided tube, bellows, etc. At the same time, various specifications of fluoroplastics can be customized and processed according to customer requirements.

More news

Landline: 0755-29979617

Cell phone: 15818669373

Add WeChat, free sample

Follow the corporate public account

Shenzhen Dankai Technology Co., Ltd.

Address: Area B, 4th Floor, Building 1, North Yongfa Science and Technology Park, Yanchuan North, Chaoyang Road, Songgang Town, Bao'an District, Shenzhen

Tel: 0755-29979617 23127719 23127819

Fax: 86-0755-29979492

Follow us

Page copyright©1998-2024 Shenzhen Dan Kai Technology Co., Ltd. Guangdong 粤ICP备12071381号