Welcome to the official website of Shenzhen Dankai Technology Co., Ltd.!

Sitemap | contact us | Online message | CN

Telephone:

+8615158121839Hot key words:Polyperfluoroethylene propylene(FEP/F46) PTFE Teflon series PFA PVDF

News

Telephone:

+8615158121839Information details

The difference between nylon and PTFE film

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2007-05-21 15:21

- Views:

The difference between nylon and PTFE film

- Categories:Industry news

- Author:Miss PTFE tube

- Origin:Miss PTFE tube

- Time of issue:2007-05-21 15:21

- Views:

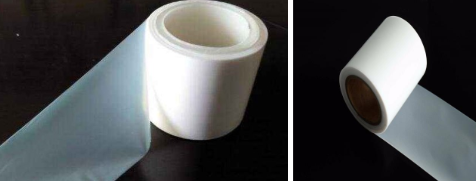

1. Teflon film, also known as polytetrafluoroethylene film, Teflon film, and f4 film, is made of suspended polytetrafluoroethylene resin by molding, sintering, and cooling into a blank, then turning and rolling.

The film formed by turning is a non-directional film, and the non-directional film becomes an oriented film after being calendered. The non-oriented film is calendered 1.1-1.8 times as a semi-oriented film. Teflon film is used as capacitor medium, as wire insulation, electrical instrument insulation, and dense gasket. It has high crystallinity, tightly arranged molecular orientation, and low porosity, so the Teflon film has been greatly improved.

PTFE film is divided into PTFE color film, PTFE activated film and F46 film.

Polytetrafluoroethylene color film is made of suspended polytetrafluoroethylene resin added with a certain amount of coloring agent, then molded and sintered into blanks, then turned and calendered into red, green, blue, yellow, purple, brown, black, and orange PTFE directional or non-directional color film in thirteen colors such as, white, etc. Although a certain amount of colorant is added to the PTFE color film, it still has good electrical insulation and is suitable for the insulation and classification of wires, cables, and electrical devices. Although a certain amount of colorant is added to the PTFE color film, it still has good electrical insulation and is suitable for the insulation and classification of wires, cables, and electrical devices.

PTFE activated film is a film made of PTFE film, filling film and color film, and then surface activation treatment. Adding pigments, glass fiber, carbon fiber, graphite, bronze powder and other fillers to the product, the performance is further improved after activation treatment, and it can be compounded with rubber, metal, etc., or special tape can be made to meet the design requirements. It is widely used in light industry, military industry, aerospace, oil field and other fields.

F4 film has the most significant withstand voltage strength and the advantages of breakdown voltage. Used as capacitor medium, as wire insulation, electrical instrument insulation, and sealing gasket. An oriented film formed by calendering PTFE turning film by hot roller rolling. It has high crystallinity, tightly arranged molecular orientation and low porosity. Therefore, PTFE film has been greatly improved, especially It is more obvious withstand voltage strength.

Figure 1: Teflon film source: Shenzhen Dankai

Second, the difference between nylon and PTFE

A special pipe made of polytetrafluoroethylene (PTFE commonly known as Teflon, plastic king) material after extrusion and sintering, drying, high-temperature sintering, and shaping. Teflon is also called Teflon, Teflon, Teflon, Teflon, Teflon, PTFE, Plastic King, and Teflon in English. It is widely used in machinery, electronic appliances, automobiles, aerospace, and chemicals. , Computers, electric heating, military, communications and other important technology industries, such as miniature transformers.

Nylon was developed by the outstanding American scientist Carothers (Carothers) and a scientific research team under his leadership. It is the first synthetic fiber in the world. The emergence of nylon has given a new look to textiles. Its synthesis is synthetic A major breakthrough in the fiber industry is also an important milestone in polymer chemistry.

The density of PTFE is generally greater than 2, while the density of nylon is about 1.2. The density of PTFE is relatively dense, high temperature resistance and hardness are relatively better, while nylon tube is softer, and the high temperature resistance is worse than that of PTFE tube, but because it is relatively soft, it can adapt to more terrain. In terms of price, PTFE tubing is slightly more expensive than nylon tubing.

PTFE product characteristics

1. High chemical stability: can withstand all strong acids, including aqua regia, hydrofluoric acid, concentrated hydrochloric acid, nitric acid, fuming sulfuric acid, organic acids, etc., strong alkalis, strong oxidants, reducing agents and various organic solvents . It is very suitable for feeding high-purity chemicals.

2. Low coefficient of friction: The coefficient of friction is generally only 0.04, which is a very excellent self-lubricating material, and the coefficient of friction does not change with changes in temperature. 3

3. Excellent anti-sticking property, and the inner wall of the tube is not easy to adhere to colloids and chemicals.

4. Excellent aging resistance, can be used outdoors for a long time.

5. Excellent electrical insulation performance: PTFE is a highly non-polar material with good dielectric properties, great resistance, and a dielectric constant of about 2.0, which is the smallest among all electrical insulation materials.

6. Part of the tube has high transparency, and the internal fluid condition can be easily observed.

Picture 2: PTFE tube source: Shenzhen Dankai

Shenzhen DanKai Technology Co., Ltd. (ShenZhen DanKai Technology Co.,ltd.), whose predecessor is Dongguan Dandi Insulation Material Co., Ltd. Fluoroplastic Material Factory, established in 1998, specializes in FEP, PFA, PTFE and other fluoroplastic pipes R&D, production and sales of rod, sheet and film products and other insulating materials. The company has a senior R&D team with international standards and a production line of fluorine plastic products imported from abroad. Some fluoroplastic products have passed ISO9001, SGS, FDA certification, and have been fully affirmed by domestic and foreign cooperative customers such as Huawei, Foxconn, Midea, ZTE, Intel, and AirTAC. The main products of the company are: ①Tubes: Ptfe tube, Fep tube, Pfa tube, Pvdf tube; ②Heat shrinkable tube: Ptfe heat shrinkable tube, Fep heat shrinkable tube, Pfa heat shrinkable tube, Pvdf heat shrinkable tube; ③Plate rod Membrane: Ptfe board and rod film, Fep board and rod film, Pfa board and rod film, Pvdf board and rod film; ④Insulation materials: silica gel, PE, PVC, UPE, etc.; ⑤Special category: PFA imported connector, spiral tube, spring tube , Rotary cut tube, welding rod, tee, straight-through, gasket, joint, taper rod, flared tube, sealing tube, braided tube, bellows, etc. At the same time, fluorine plastic products of various specifications can be customized and processed according to customer requirements.

More news

Landline: 0755-29979617

Cell phone: 15818669373

Add WeChat, free sample

Follow the corporate public account

Shenzhen Dankai Technology Co., Ltd.

Address: Area B, 4th Floor, Building 1, North Yongfa Science and Technology Park, Yanchuan North, Chaoyang Road, Songgang Town, Bao'an District, Shenzhen

Tel: 0755-29979617 23127719 23127819

Fax: 86-0755-29979492

Follow us

Page copyright©1998-2024 Shenzhen Dan Kai Technology Co., Ltd. Guangdong 粤ICP备12071381号